The Ultimate Guide to Commercial Refrigeration Repair: Typical problems and vital steps Described

Usual Industrial Refrigeration Issues

When running business refrigeration systems, companies might encounter a number of typical problems that can impact the efficiency and functionality of the equipment. Fluctuating temperature levels within the refrigeration system can lead to food perishing, enhanced energy usage, and endangered top quality and safety criteria.

Another common problem is refrigerant leakages. Leaks can arise from damage, poor setup, or manufacturing flaws. Reduced cooling agent degrees not just prevent the system's cooling ability however can likewise result in compressor failing if left unaddressed.

Furthermore, ice accumulation on evaporator coils is a regular concern. Ice build-up restricts airflow, creating the unit to function harder and eat more energy. Routine cleaning and upkeep of the coils can assist prevent this issue.

Vital Tools for Repairing Refrigeration Systems

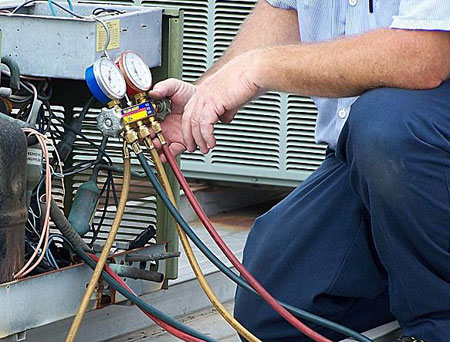

Making use of the suitable tools is crucial for properly repairing business refrigeration units to make certain optimal performance and long life. A collection of essential tools is crucial for service technicians to identify and fix problems promptly. Amongst the fundamental devices needed are manifold determines for checking refrigerant stress, refrigeration wrenches for tightening up or loosening up installations, a multimeter for screening electric parts, and leakage detection tools such as digital leak detectors or ultraviolet dye kits. Additionally, vacuum pumps are vital for evacuating air and moisture from the system before cooling agent recharge. commercial refrigerator repair.

In the world of specialized tools, tube cutters and flaring devices are important for functioning with copper tubes, while a recuperation device is needed for securely removing cooling agents. Additionally, a temperature level weapon can be valuable for rapidly recognizing temperature differentials within the system. Buying top notch devices not only enhances effectiveness during fixings yet also adds to the accuracy and dependability of the maintenance work executed on industrial refrigeration systems.

Step-by-Step Troubleshooting Guide

The following step is to check the temperature level controls and settings to ensure they are working correctly. This includes examining the thermostat, thaw timer, and other control systems to verify that they are controling the temperature level as meant. If any kind of discrepancies are found, replacements or modifications might be necessary. Toronto commercial refrigerator repair.

Ultimately, the professional ought to examine the condenser and evaporator coils for dust or particles accumulation, which can hinder proper air conditioning. Cleansing these parts can frequently deal with concerns with temperature level guideline and performance.

Preventative Upkeep Techniques

Implementing regular preventative upkeep actions is essential for guaranteeing the long life and ideal efficiency of commercial refrigeration systems. By sticking to an aggressive upkeep schedule, organizations can lessen the threat of expensive break downs, prevent downtime, and expand the lifespan of their refrigeration tools.

One vital preventative upkeep method is routine cleansing of condenser coils. With time, these coils can accumulate particles, dust, and dirt, which can restrain warmth transfer and decrease the system's performance. By cleaning up the coils periodically, companies can ensure that the refrigeration system runs at peak performance.

Additionally, inspecting and changing worn gaskets on doors is another essential upkeep job. Damaged gaskets can result in air leakages, causing the refrigeration system to function tougher to keep the desired temperature level. By replacing defective gaskets promptly, services can enhance energy performance and prolong the life of the equipment.

Incorporating these preventative maintenance methods right into a thorough upkeep plan can assist organizations optimize the performance and integrity of their industrial refrigeration systems.

Specialist Repair Work Vs. DIY: Advantages And Disadvantages

Involving a professional fixing service for official statement business refrigeration systems provides distinct benefits over attempting do it yourself fixings. Industrial refrigeration devices are complex systems that need specialized understanding and abilities to diagnose and repair successfully. Experts have the training and experience to determine issues accurately, resulting in quicker and more exact fixings. They additionally have accessibility to advanced tools and tools that might not be conveniently offered to the typical individual.

Additionally, professional fixing services frequently provide service warranties on their job, providing you satisfaction understanding that the work is assured. Trying to repair a business refrigeration system on your own can result in more damages if important source not done appropriately, potentially leading to even more costly fixings down the line. Furthermore, DIY repair services may nullify any kind of existing service warranties on the devices, leaving you entirely liable for any kind of future issues that may occur. While do it yourself repair work may seem economical originally, the lasting advantages of specialist fixing solutions exceed the risks and uncertainties associated with attempting repairs on your very own.

Conclusion

In conclusion, comprehending usual commercial refrigeration issues, having the necessary tools for repair service, complying with a detailed troubleshooting overview, and implementing preventative upkeep techniques are key elements of maintaining and repairing industrial refrigeration systems. While expert repair service solutions may offer know-how and efficiency, DIY repair services can also be an affordable choice for those with the essential skills and knowledge. Inevitably, routine maintenance and prompt repair services are vital for ensuring the appropriate performance of industrial refrigeration systems.

Recognizing the vital actions for business refrigeration repair service and being able to identify usual concerns are vital skills for any organization owner or upkeep employees. In this extensive guide, we will check out the fundamental actions and typical concerns in industrial refrigeration repair, furnishing you with the expertise required to address these difficulties effectively.

Involving an expert repair work solution for industrial refrigeration systems provides distinctive you could try these out advantages over attempting DIY repair services. Trying to repair a business refrigeration system yourself can lead to additional damages if not done properly, potentially resulting in more expensive fixings down the line.In verdict, comprehending common business refrigeration concerns, having the essential tools for fixing, complying with a step-by-step troubleshooting guide, and implementing preventative upkeep strategies are vital components of preserving and repairing industrial refrigeration units.